Direct Drive vs Bowden Extruder

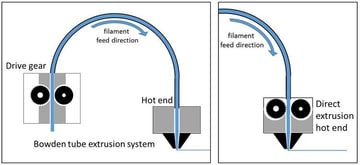

Fused-deposition modeling (FDM) 3D printers use either direct or Bowden extruder setups. And while the basic principle is the same – the use of an extruder to push filament through a heated nozzle – the difference lays in where that extruder sits.

In a direct extrusion system, the extruder is mounted on the printhead and pushes the filament directly into the hot end. Meanwhile, a Bowden system usually has the extruder mounted on the frame of the printer. As such, the filament travels through a PTFE tube to reach the printhead.

Both setups have the same outcome, but there are some consequences of the different designs. Let’s explore the pros and cons of these two options!

Direct Extrusion System

With a direct extrusion setup, the extruder pushes the filament directly into the nozzle. This method is helpful for many reasons, but it also has some downsides. Let’s take a look.

PROS

- Reliable extrusion: Since a direct extruder is mounted to the printhead, the motor can easily push filament through the nozzle, resulting in fewer extrusion-related issues.

- Better retraction: Because the extruder is close to the nozzle, it can more easily retract filament.

- Less-powerful motor: Due to the short distance between the extruder and the nozzle, less torque from the motor is required to push the filament.

- Wider range of filaments: Although less relevant now as in the early RepRap days, a direct extruder is generally considered to be more compatible with a wider range of filaments. This is especially the case with flexible and abrasive materials.

CONS

- Vibrations: With the extruder mounted to the printhead, weight is obviously added. This extra weight adds speed constraints, causing more wobble and possibly a loss of accuracy in X and Y movements.

- Cumbersome maintenance: In some direct extrusion setups, the extruder being mounted to the printhead can make accessing certain parts for maintenance more difficult.

3D printers that have direct extrusion setups include Prusa’s i3 MK3S+, the Anycubic Kobra, and Creality’s CR-10 V3.

Bowden System

Unlike in a direct extrusion setup, in a Bowden system, the extruder is mounted on the printer’s frame. It pushes and pulls filament through a long PTFE tube (called a Bowden tube) and into the hot end. Naturally, this system also has pros and cons.

PROS

- Cleaner movements: Since in a Bowden setup the extruder is mounted on the printer’s frame rather than on the print head, much less weight is on the carriage. Less weight means faster, quieter, and higher quality prints.

- Larger build volume: Though not always the case (depending on a printer’s construction), a Bowden setup may allow for a smaller printhead carriage, which may in turn allow for increased build volume.

CONS

- More powerful motor: Because the extruder must push and pull filament through a long tube, a certain amount of friction exists between the two. This friction calls for more torque to adequately control the filament.

- Slower response time: Friction in the Bowden tube also translates to a more noticeable delay between extruder and nozzle. These extruders therefore require faster acceleration in extrusion and retraction to deposit properly and avoid stringing.

- Material complications: Some flexible and abrasive filaments can easily bind or wear in Bowden tubes, especially in older models of printers.

To name a few, Elegoo’s Neptune 2S, Prusa’s Mini+, and Creality’s Ender 3 series use Bowden extruders – except for the Ender 3 S1, which replaced it with the Sprite direct extruder.

Final Thoughts

So, which system is better? It depends. Before you decide which extrusion option to use for your printer, you should consider some important factors.

The first is frame and motion system stability. Many delta printers, for example, can’t easily support the weight and vibrations that come with a direct extruder. If, however, your Cartesian or CoreXY printer has a sturdy structure, printing with a direct extruder should be no problem.

Speed is also a deciding factor. If your priority is fast, precise printing with standard materials, a Bowden extruder setup will be more satisfactory.

Lastly, you should consider the materials you would like to print with. If you’re interested in flexible or abrasive filaments, a direct extrusion system is likely the one for you.

You don’t need to fret if you’ve already got your 3D printer and want to change from a Bowden to a direct extrusion setup; check our guides for the Ender 3 (V2/Pro) and 5.